A blog of the Science and Technology Innovation Program

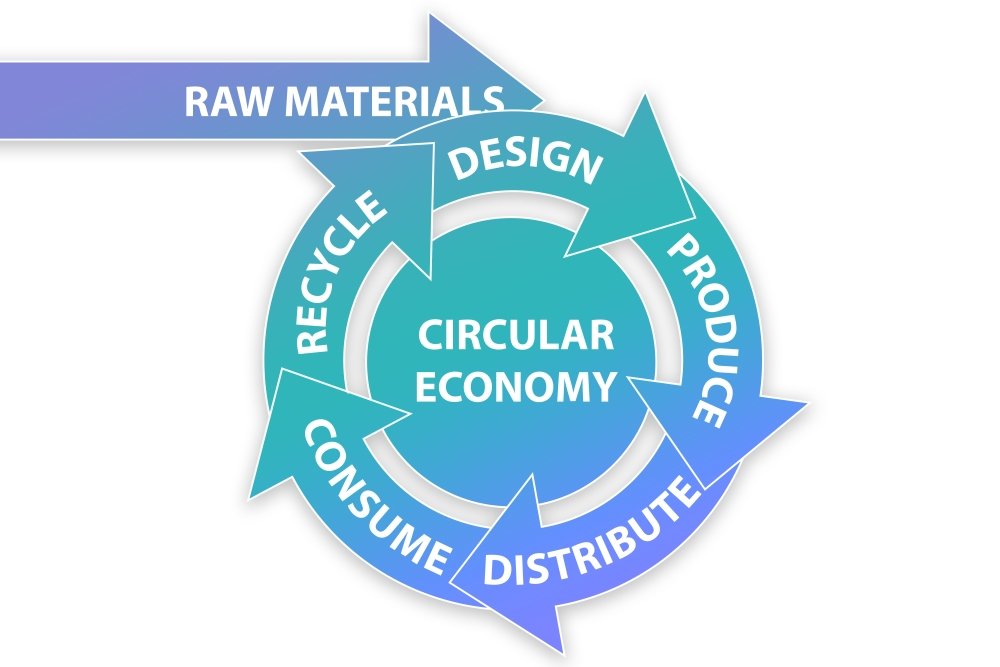

The circular economy is a framework that can reduce the environmental impact of production by promoting the repair, reuse, and recycling of consumer goods. While promising to close the loop on waste, this framework presents many challenges to implementation. Can publicly available or “open” tools address these challenges in a way that is impactful and accessible?

Governments and industries around the world have set sustainability agendas to reduce their environmental impact by 2030 and avoid irreversible effects of climate change. Just this year, Apple announced it would reduce its emissions by 75% before 2030, Delta Airlines and BP pledged to go carbon neutral, and the EU has allocated 37% of its coronavirus recovery packages to sustainability initiatives. With more ambitious environmental timelines and goals than ever before, it is evident that the “take-make-waste” approach to the economy needs to be addressed quickly and in a way that is impactful on a global scale.

The circular economy is a framework that reconfigures the “take-make-waste” approach by promoting the use of renewable energy sources, recyclable materials, and repairable consumer goods. Key to this framework is tackling the waste stream to step closer to zero waste and reduce GHG emissions. As Eli Patton recently wrote for New Security Beat, there's a growing governmental interest from bodies like the United Nations in "a combined approach of less plastic, new materials, and more recycling as necessary to bend the curve on plastic pollution." To reach sustainability goals, it is essential that this infrastructural approach is applied to other extractive industries and materials, in addition to plastic. To do so would impact everything from the production to the disposal of products, seeking to keep them out of the landfill.

This framework is still conceptual; one of the missing pieces to enact the circular economy approach is the tools to do so. One solution might be found in open tools, a term used by the open source hardware and software movement as those developed and released so that “anyone can make, modify, modify, distribute, and use” them. In this article, open tools will be defined more broadly as tools available, transparent, and usable to the general public and can include hardware, software, website platforms, data and more. Relevant to the circular economy framework, open tools can often be more accessible, both technically and financially, which in turn can allow for broader impact, and can accelerate data collection and innovation.

Innovation is already happening in this space, with developers designing tools that target key touchpoints of the circular economy: waste free design, disposal of plastics, and, perhaps most critically, keeping products out of the landfill entirely. To truly impact key touchpoints of the circular economy, tools require rapid innovation and widespread implementation. The following case examples demonstrate open tools’ potential to do so.

Open Materials Database for Waste Free Product Design

Materials data, in the form of a publicly accessible database, could aid professionals in reducing the use of wasteful materials. Currently, wasteful materials are either extracted or processed in a wasteful manner, difficult to recycle, and/or toxic to humans and the environment. Most materials data is either not provided or unknown by materials suppliers. The data is also difficult to track through complex supply chains. Without information on the environmental impact of materials, engineers and designers do not have the tools to select “wasteless” materials for their products.

A materials database could be modeled after Portico, a library for building materials developed by Google. Though this tool was not publicly available, it has features of openness that could be incorporated into an open database. For instance, the information was shared in an open style. Designers could search for a building material of interest in the platform to find a rating of the material’s health. Data on the materials’ chemical composition, health risk, and sustainability was displayed in an easy to visualize manner, empowering professionals with the necessary knowledge to design waste free products.

If a material was not available, the designers could then send a request to suppliers for the information. The suppliers could then complete the assessment and upload the product information into the database. This feature helps point out the gaps in data and provides action to fill them. Portico, though put on pause in 2018, exemplifies how using concepts of openness can accelerate the collection of essential materials data to enable waste free design.

By making a Portico-style, materials database open, its impact could be broadened. If such data was proprietary, access or rights to data would need to be purchased, creating financial barriers for organizations or communities with limited resources to access this information. Additionally, as seen in the more open features of Portico, an open database would eliminate the need to “reinvent the wheel.” Professionals would be able to access data that had already been collected, instead of having to build their own database from scratch, reducing time barriers to data collection.

Open Recycling System to Close the Loop on Plastic Waste

The circular economy requires the invention of new technologies to solve complex waste management issues, such as the disposal of plastic. Although plastic can be recycled, the collection, transportation, and centralized recycling of plastics is uneconomical and inefficient due to the material’s high volume to weight. The development of technological solutions to waste management problems, like plastic recycling, can be accelerated using open tools.

Recyclebot and Precious Plastics are open tools that enable the decentralized recycling of plastic. The Recyclebot converts consumer plastic waste into material input filaments for 3D printing and Precious Plastics turns plastic into construction materials, furniture, and other novel products. These tools are considered open because their design files are available online so that anyone can view and contribute to the projects. In the Precious Plastic project, this has led to 80,000 active users worldwide contributing their knowledge and expertise to the design and development of the tool. Thus, open tools can accelerate innovation through crowd contributions and participation in the design process.

Publicly available design files can also permit the modification and reproduction of the tool, as in both Precious Plastics and Recyclebot. This enables individuals and organizations to build their own tools, and even customize it to their personal needs. This tends to reduce costs compared to purchasing an “off the shelf” tool and could reduce maintenance costs of waste management tools. For example, if an open tool breaks, instead of having to purchase a new part or pay for repair service, a part could be repaired or built locally from the design files. More than 1000+ groups are building or using the recycling system, demonstrating the ability of the open paradigm to reduce cost and broaden access to technological resources.

Open Repair Platform to Keep Products Out of Landfill

Reducing the disposal of consumer goods is key to closing the loop on waste. To do so, products must be designed to last longer and consumer culture needs to drastically shift to value repair. The lack of common knowledge on repair of items, like electronics and appliances, is one of the many challenges to achieving this.

iFixit is a platform that can help tackle this problem by providing openly available information on repair. This website has over 60,000 repair manuals for over 30,000 devices. Anyone can access easy-to-follow repair guides, contribute to improvements of repair guides, answer questions on the forum, or upload their own repair guide. This can help increase repair data and fosters an exchange of technical skills necessary to increase product longevity. Furthermore, the page has publicly accessible teardown guides that take apart devices and rate how repairable they are. This can guide users to purchase items that have high repairability ratings as well as help professionals identify the design features that inhibit their products from being repairable. All the platform’s content is licensed under Creative Commons BY-NC-SA 3.0, a license that encourages the information to be shared.

Though a cultural shift in consumer behavior is needed for this tool to be fully utilized, the publicly available guides increase access to knowledge that is traditionally limited to those trained in technical fields. Instead of paying for an engineer or technicians to fix your appliance or purchasing a new one, individuals can access information and develop skills to repair their product for free. This is invaluable for consumers and producers around the world to keep products out of landfills.

What’s Next?

These examples demonstrate how open tools can advance the goals of the circular economy by accelerating data collection and innovation. Whether it be through reduced maintenance costs, saving time, or increased access to technical knowledge, it is evident that these tools are also more accessible than proprietary alternatives. Open tools’ benefit of broadened accessibility is especially important, as implementing a circular economy and closing the loop on waste is an interconnected, global effort. With more entities able to access and use tools to solve challenges associated with the circular economy, the more communities are able to experience the benefits of a cleaner world.

Although open tools broaden access, there are still significant barriers for these tools to be widely adopted. In order to increase the impact of and access to open tools, the following issues must be addressed:

1. The Digital Divide: Open tools are often made publicly available via the internet. Globally, about 3.6 billion people do not have access to the internet. Even those who have access may have unreliable connectivity or limited access to a computer. Gaps in digital literacy and technical skills pose barriers to building an open tool like Precious Plastics or Recyclebot. Thus, more infrastructure development for universal access to quality internet and digital literacy education, both domestically and globally, are needed. It is also essential for the open tools community to design, advocate, and work with communities that might face these barriers.

2. Discoverability: Open tools focused on reducing waste are not easy to find. Open tool platforms, such as GitHub and Arduino, could have waste management or circular economy as a search or topic category to improve discoverability.

3. Incentivize Openness: Most tools developed for a circular economy are not open. Most industries with high waste production are not using open tools. Top-down incentives such as open innovation challenges and competitions centered on waste issues could help increase the development of open tools for a circular economy. Incentives for the corporate sector to invest in or use open tools could increase impact as well.

A missing piece to the circular economy is the availability of the tools to empower action. More widespread access to and adoption of these tools can be achieved by addressing these barriers. In this way, the use of open tools can become a more impactful method for driving a circular economy, and a more equitable, waste-free world.

References

Aitamurto, T., Holland, D., & Hussain, S. (2015). The open paradigm in design research. Design Issues, 31(4), 17-29. https://doi.org/10.1162/DESI_a_00348

Sanchez, F. A. C., Lanza, S., Boudaoud, H., Hoppe, S., & Camargo, M. (2015, August). Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Annual international solid freeform fabrication symposium, ISSF 2015 (pp. 1591-1600). https://hal.univ-lorraine.fr/hal-01523136

Zhong, S., & Pearce, J. M. (2018). Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resources, Conservation and Recycling, 128, 48-58. https://doi.org/10.1016/j.resconrec.2017.09.023

Author

Science and Technology Innovation Program

The Science and Technology Innovation Program (STIP) serves as the bridge between technologists, policymakers, industry, and global stakeholders. Read more